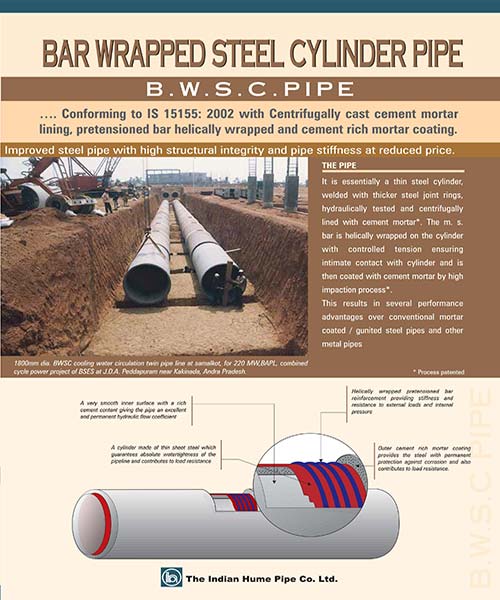

BAR WRAPPED STEEL CYLINDER PIPE (BWSC)

The Pipe

It is essentially a thin steel pipe cylinder; Welded with thicker steel joint rings at the ends, hydraulically tested and centrifugally lined with cement mortar. The M.S bar / wire is helically wrapped on the cylinder with controlled tension ensuring intimate contact with cylinder and is then coated with cement mortar by high impaction process. This results in several performance advantages over conventional mortar gunited steel pipes and other metal pipes.

Choice of Joints

The joint rings are made of thicker steel plates. The field joint can be over lapping /sliding, butt Welded or with confined rubber rings to suit requirement of the client. A joint is so designed that it will be water tight under all service conditions.

Optimum Design

The pipe is designed to resist internal hydrostatic pressure by steel cylinder and pretensioned helically wound rod. Hence, pipe can be custom designed by selecting steel-cylinder thickness, bar diameter and spacing .This flexibility in design can result in substantial saving.

Structural Integrity

Since rods are helically wrapped under tension , the structural integrity of these pipes is greatly enhanced because of the interlocking of steel elements of the pipe. This composite construction greatly increases rigidly of the pipe, beam strength and resistance to impact.

Corrosion Resistance

The cement mortar encasement maintains the steel elements in a highly alkaline environment (pH of 12.5 or greater) in which galvanic corrosion is permanently inhibited. Although, rarely required, supplemented protection can be provided for any unusual surrounding conditions.

Stiffness

Stiffness of pipe is the result of the keying action of the pretensioned rod wrap over steel cylinder and the coating. From the graph of pipe stiffness Vs. Diameter Vs. types of pipes, it is observed that these pipes are many times stiffer than steel pipes lined and coated with cement mortar, PVC & Ductile Iron Pipes. hence, less expensive bedding and side support during installation. This will result in added economy.

Coefficient of Roughness

The smooth surface of cement mortar lining provides value of Hazan Williams constant 'C' around 140 in the formula. Because cement mortar prevents corrosion of steel pipe, the water carrying capacityBar Wrapped Steel Cylinder Pipes.is not decreased with age of pipe.

Diameter, Pressure & Length

These pipes can be made from 250 mm to 1600 mm diameters for working pressure up to 25 Kg/cm2 . Length of each pipe shall be between 5 - 6 meter. Longer length pipes are also possible for large requirements.

Economy

These pipes are made of steel plates of lesser thickness than conventional Steel pipes. The additional strength for internal pressure and external load is provided by less expensive tensioned mild steel rod than steel plates. It is stiffer than conventional steel pipe because of tensioned rod and hence the bedding and side support cost is less than conventional steel pipes. In most situations it is substantially economical as compared to conventional Steel pipes , Cast iron and Ductile iron pipes.

Reliability

Thousands of Kilometers of these pipe lines are in service in Europe and United States of America since 1942 as transmission and distribution water pumping mains, sea water mains, sewage water disposal mains etc.

highlighted projects

| Project | Length |

|---|---|

| 113 Coastal habitations | 53 km |

| Nalgonda phase IV | 34 km |

| Mahaboobnagar | 30 km |